Case Study

Icebreaker: Textile waste recovery

Created by

Redress

,

2022

Textile waste is an environmental issue, with an estimated 92 million tons created annually from the fashion industry.1 It is also a financial one, with more than US$500 billion of value being lost annually due to clothing under-utilisation and lack of recycling.2 There is a real opportunity for collaboration between brands, designers, and manufacturers to recognise waste hotspots across the supply chain in order to maximise material use and propel circular fashion.

In this case study, we follow the finalists of the Redress Design Award 2022 during their challenge to identify textile waste along Icebreaker’s supply chain and come up with innovative solutions for it. This challenge highlights the many opportunities that exist in revaluing textile resources.

The challenge

In partnership with icebreaker, the ‘Move to Natural’ challenge was held over an intensive six hours. Our Redress Design Award 2022 finalists joined forces with a diverse selection of students from the Hong Kong Polytechnic University, emulating the composition and collaboration of real-world design and product development teams. Separated into groups, designers and students worked in conjunction with the Icebreaker teams to understand where textile waste is created within their supply chain and come up with innovative solutions for it.

Icebreaker wanted a solution that could reuse their iconic knitted fabric, Bodyfit 200. This incredibly versatile fabric is made from 100% merino and creates products that range from tees to tights, and beanies to underwear. What stands out about this fabric is its durability and recyclability. Within the Icebreaker supply chain, leftovers of this prolifically used fabric can be found in both yarn and fabric form, with offcuts varying in size, amount, colours, and shapes.

Brand DNA was an important aspect to be incorporated into the design solution for this challenge. The Icebreaker identity embodies disruptive design and innovation, so the judges were eager to see how each of the teams infused these concepts into their solutions.

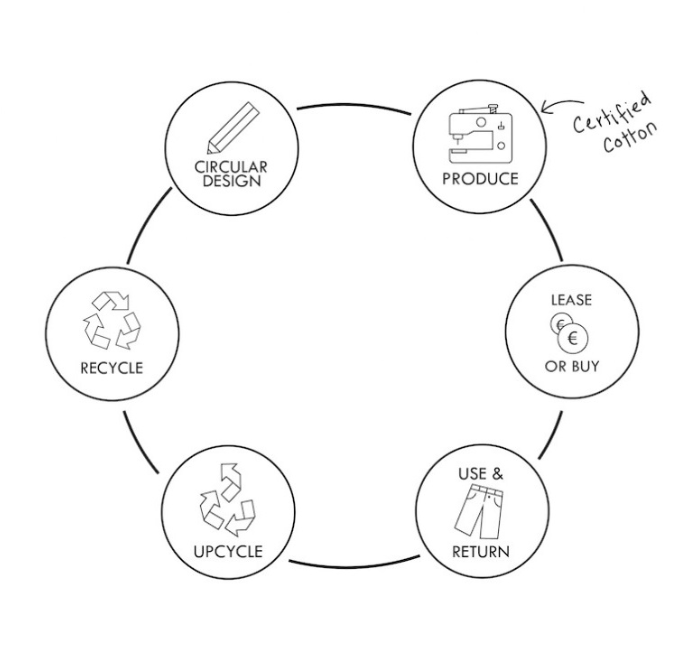

Each team was required to deliver a five-minute business concept pitch, introducing not only the product they’d designed, but also an end-to-end lifecycle consideration so that waste would be addressed from the outset. This pitch included: the insight, the problem, and how their concept could resolve the problem.

The Winning Idea

The winning team successfully identified three key hot spots within the early stages of the processing part of the BF200 supply chain.

Credit: Redress Design Award

Their solution uses the BF200 waste generated during the ‘Tops’ phase (before the yarn is spun for knitting). By collaborating with the factories, this valuable waste could become padding, which the winning team recycled as an internal layer for a jacket that also used BF200 as the outer fabric.

Credit: Redress Design Award

The team used a familiar silhouette and style for existing customers, while also attracting younger consumers by fashioning BF200 offcuts into designs on the back of their garments to create unique limited editions. The padding solution worked to utilise the waste at the early stages of the supply chain and produced an opportunity to elevate Icebreaker products, which appealed to the judges as unique marketability. Using recycled materials as a design feature on familiar products would also appeal to the conscious consumer.

Credit: Redress Design Award

The judges’ feedback on this concept included a strong recognition of the Icebreaker brand DNA; well-thought-out considerations on the production stream from end-to-end, and a brilliant adoption of the Icebreaker phrase ‘from Sheep to Shirt’. The team also considered price control, which is an important factor in creating commercial appeal.

The fashion industry constantly requires rapid solutions from designers. Consider what you would do in this challenge and how you would work with others in such a short amount of time. In the video, our finalists had the chance to put their skills to the test with industry practice. Are you ready to take on the challenge?

About the Contributor

Icebreaker is part of the Outdoor & Action Sports division at VF Corporation. Organised in 1899, VF Corporation is a global leader in branded lifestyle apparel, footwear, and accessories, with global iconic brands, 64,000 associates and US$12.4 billion in revenue. Their businesses and brands are organised into four categories called coalitions, comprising: Outdoor & Action Sports, Jeanswear, Imagewear, and Sportswear. While VF is highly diversified across brands, products, distribution channels, and geographies, their One VF culture and approach to doing business provide a unique and powerful competitive advantage.

The Hong Kong Polytechnic University, with 85 years of proud tradition and ranking among the world’s top 100 institutions, aspires to be a leading university with world-class research and education. Their School of Fashion and Textiles is committed to cutting-edge research, and its outstanding research output, both in quantity and quality, ranks top among fashion and textile institutions in the world. In this challenge, PolyU students worked with finalists to provide their insights, adding diversity to the discussions and opportunities to work with new people.

Footnotes

1 Global Fashion Agenda and The Boston Consulting Group, Inc. (2017), Pulse of the Fashion Industry

2 Ellen MacArthur Foundation (2017), A New Textiles Economy: Redesigning Fashion’s Future